Izinto eziyinxalenye yeevalvu zebhola: Isikhokelo esineenkcukacha esenziwe nguMvelisi weevalvu ze-NSW

Iivalvu zebholaazinamsebenzi kwiinkqubo zolawulo lolwelo lwemizi-mveliso, zibonelela ngokuthembeka, ukuqina, kunye nolawulo oluchanekileyo lokuhamba kwamanzi. Ukuqonda izinto zazo kubalulekile ekwenzeni ngcono ukusebenza kunye nobude bexesha. Njengenkokeliumboneleli wevalvu yebhola, Umvelisi weValve ye-NSWIdibanisa ubunjineli obuphambili kunye nezixhobo eziqinileyo ukubonelela ngeevalvu ezihlangabezana nemigangatho yehlabathi. Esi sikhokelo samagama angaphezu kwe-1000 sichaza izinto eziphambili zeevalvu zebhola, imisebenzi yazo, kunye nezinto eziqwalaselweyo kuyilo.

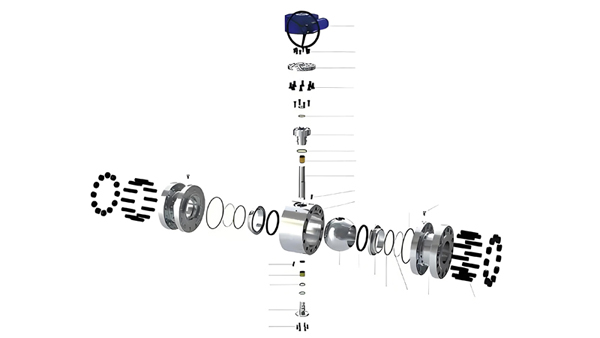

Umzimba weValve yeBhola: Isiseko seSakhiwo

Iumzimba wevalvululwakhiwo oluphambili lwevalvu yebhola, egcina zonke izinto zangaphakathi kwaye iqhagamshela kwiinkqubo zemibhobho.Umvelisi weValve ye-NSW, imizimba yeevalvu yenziwe ngokuchanekileyo kusetyenziswa izixhobo ezinje:

- Intsimbi yekhabhoni:Uhlobo lwentsimbi yokuphosa kunye nohlobo lwentsimbi eyenziweyo

- Yenziwe ngentsimbi eshayinayo(304, 316,intsimbi engenasici kabini)

- Iialloy ezikhethekileyo(Inconel, Hastelloy)

- Ii-Alloys zeBronze(B62 C95800, C63000, C95500, njl.njl.)

- Jula i-ayini(kwizicelo eziphantsi koxinzelelo)

Imisebenzi ephambili:

- Ivumela iinxalenye zangaphakathi: Igquma ibhola, isihlalo, kunye nesiqu ngokukhuselekileyo.

- Ukuhlanganiswa kweMibhobho: Iquka uqhagamshelo olujijekileyo, olunemisonto, oludibeneyo, okanye olunamathelisiwe ukuze lufakelwe olungenako ukuvuza.

- Ulawulo loxinzelelo: Yenzelwe ukumelana noxinzelelo lwenkqubo ukuya kuthi ga kwi-10,000 PSI, kuxhomekeke kwizinto eziphathekayo kunye nodidi.

Umvelisi weValve ye-NSWIbonelela ngemizimba yeevalvu ezenziwe ngokwezifiso ezenzelwe iimeko zobushushu obuphezulu, ezirhabaxa, okanye ezirhabaxa, ukuqinisekisa ukuthotyelwa kwemigangatho ye-API, i-ANSI, kunye ne-ASME.

Ibhola: I-Core Flow Control Element

Iibholasisiqwenga esiphambili sevalvu, sijikeleza ngama-90° ukulawula ukuhamba kolwelo.Umvelisi weValve ye-NSWivelisa iintlobo ezimbini:

- Iibhola Ezidadayo: Ilungele uxinzelelo oluphantsi ukuya koluphakathi.

- Iibhola zeTrunnion: Kwiinkqubo ezinoxinzelelo oluphezulu (umz., ioyile negesi).

Iimpawu zoYilo:

- Izixhobo: Intsimbi engatyiwayo, iiseramikhi, okanye i-PTFE-coated ukuze ikwazi ukumelana neekhemikhali.

- Iintlobo zeBore: Izibuko elipheleleyo (ukuhamba kwe-100%) xa kuthelekiswa nezibuko elincitshisiweyo (ukuhamba kwe-80%).

- Iindlela zokutywina:

–Izitywino ezithambileyo: I-PTFE okanye ii-elastomers zokuthintela ukuvuza okungavuziyo.

–Izitywina Eziqinileyo: Isinyithi-kwisinyithi xa kushushu kakhulu.

In Iivalvu zebhola ezineendlela ezintathuukusukaUmvelisi weValve ye-NSW, iibhola ezinamachweba amaninzi zivumela ukuphambuka, ukuxuba, okanye ukuvala ukuhamba kwamanzi kwiinkqubo ezintsonkothileyo.

Isihlalo seValve yeBhola: Ukuqinisekisa Ukusebenza Okungenamanzi

Iisihlalo sevalvuyenza uphawu oluqinileyo phakathi kwebhola nomzimba.Umvelisi weValve ye-NSWkusetyenziswa:

- Izihlalo ezithambileyo: I-PTFE, i-NBR, okanye i-EPDM kwizicelo ezisebenzisa ubushushu obuphantsi.

- Izihlalo Eziqinileyo: Intsimbi engatyiwayo, iStellite, okanye i-tungsten carbide yezixhobo zokurhawuzelela.

Uyilo lweZitulo ezintsha:

- Ukuvimba kabini kunye nokopha (DBB): Yahlula ukuhamba kwamanzi angasentla/asezantsi ukuze kugcinwe ukhuseleko.

- Ukuzicoca: Izikrweqe zisusa inkunkuma, zandisa ubomi besihlalo xa kusetyenzwa udaka.

- Ivalvu Yokwahlulwa Kabini kunye neValve Yokopha (DIB): Yivalvu yebhola enezibini ezimbini zokutywina izihlalo zeevalvu. Isibini ngasinye sokutywina isihlalo sevalvu sinika kuphela ukutywina komthombo omnye woxinzelelo xa sikwindawo evaliweyo, kwaye sikhupha/sikhuphe umgodi womzimba wevalvu phakathi kweendawo ezimbini zezihlalo zeevalvu ukuze kuqinisekiswe ukutywina koxinzelelo kuzo zombini iziphelo.

Isiqu seValve: Amandla okujikeleza adluliselwayo

Iisiqu sevalvuiqhagamshela i-actuator kwibhola.Umvelisi weValve ye-NSWuphawu lweziqu:

- Izixhobo: 316 intsimbi engagqwaliyo okanye i-alloy 625 yokumelana nokugqwala.

- Uyilo oluchasene nokuqhushumba: Ithintela ukuphuma kwesiqu xa iphantsi koxinzelelo.

- Ukupakisha okuKhutshwayo okuPhantsi: Iiseal ze-PTFE ezijikelezayo ze-V ziyahlangabezana nemigangatho yokukhupha umoya ebalekayo ye-ISO 15848.

Ukupakisha iValve yeBhola: Ukuthintela ukuvuza kweStem

Ukupakisha kuvala ujongano lwesiqu nomzimba.Umvelisi weValve ye-NSWizibonelelo:

- Ukupakisha okuLukiweyo kwePTFE: Ukuze ihambelane neekhemikhali (-200°C ukuya kwi-260°C).

- Ukupakisha iGraphite: Ukumelana nobushushu obuphezulu (ukuya kuthi ga kwi-650°C).

- Uyilo lweMikhuhlane ePhantsi: Ukupakisha kwe-M600/M641 kwiindawo ezinobungozi.

Iindlela Zokusebenza: Ngesandla ukuya Kwezenzekelayo

Umvelisi weValve ye-NSWinika izisombululo ezisebenzayo ezahlukeneyo:

| Uhlobo lweDrive | Izicelo | Iinzuzo |

| Ngesandla | Iinkqubo ezincinci | Ixabiso liphantsi, akukho mbane ufunekayo |

| I-Pneumatic | Iinkqubo zokujikeleza ngokukhawuleza | Ayinakuqhuma, isantya esiphezulu |

| Umbane | Iinkqubo ezilawulwa kude | Indawo echanekileyo, ukuhlanganiswa kwe-IoT |

| iHydraulic | Iimfuno ze-torque ephezulu (umz., phantsi kolwandle) | Amandla e-PSI angaphezu kwe-10,000 |

| Iqhutywa zizixhobo | Iivalvu ezinkulu ngobukhulu | Ukusebenza kakuhle, ukugcinwa okuphantsi |

Kutheni Ukhetha Umenzi weValve yeNSW

Njengomntu othembekileyoumboneleli wevalvu yebhola, Umvelisi weValve ye-NSWivelele phakathi:

- Ubunjineli BesikoIivalvu ezenzelwe i-API 6D, i-ASME B16.34, kunye ne-ISO 17292.

- Iziqinisekiso zeHlabathi: I-API 607 ikhuselekile emlilweni, i-NACE MR0175 yegesi emuncu.

- Inkxaso engama-24/7Uncedo lobuchwephesha kunye nokuhanjiswa kwezixhobo ezitsha ngokukhawuleza.

Isiphelo: Lungiselela iNkqubo yakho ngeeValvu zeBhola zePremium

Ukuqonda izinto zevalvu yebhola kuqinisekisa izigqibo ezinolwazi malunga nokusetyenziswa kwemizi-mveliso. Nokuba ufuna ivalvu yetrunion enoxinzelelo oluphezulu okanye uyilo oluneendlela ezintathu olumelana nokugqwala,Umvelisi weValve ye-NSWinika izisombululo eziphucula ukusebenza kakuhle kunye nokhuseleko.

Nxibelelana noMvelisi weValve yeNSW namhlanjeukuze ufumane isicatshulwa okanye ingcebiso yobugcisa. Jonga ikhathalogu yethu yeevalvu eziqinisekiswe yi-API ezenzelwe amashishini okucoca ioyile, igesi, iikhemikhali kunye namanzi.

Ixesha leposi: Epreli-04-2025