1. Inkcazo yohlobo lokupakisha lweGraphite

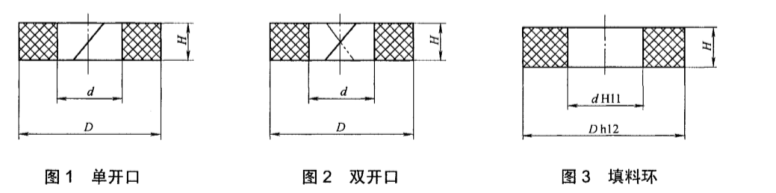

Kukho iintlobo ezintathu ezilandelayo zezalisa ezisetyenziswa rhoqo kwiiivalvu

Ukupakisha okusetyenzisiweyo kule projekthi luhlobo lokuvula olunye olukuMfanekiso 1 kunye nokupakisha okumile okwesangqa okukuMfanekiso 3. Iifoto zokwenyani zezi zilandelayo:

Umfanekiso 1 Uhlobo lokupakisha oluvula olunye

Umfanekiso 3 Ukupakisha indandatho yokupakisha

Imisebenzi yokusetyenziswa kwezi paki zimbini zingasentla iyafana, umahluko ukwimeko ezahlukeneyo zokusetyenziswa. Ukupakisha okuvula kube kanye kufanelekile ukutshintsha ukupakisha ngexesha lokugcinwa kwevalvu yemihla ngemihla. Ukupakisha kunokutshintshwa kwi-intanethi, kwaye ukupakisha iringi yokupakisha kufanelekile ukulungisa ivalvu. Isetyenziselwa ukuqhaqha nokulungisa.

2. Inkcazo yeempawu zokupakisha i-graphite

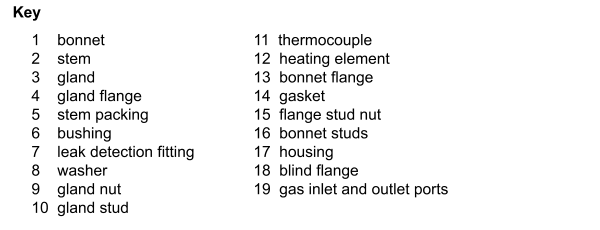

Ngokweemfuno zobugcisa zomenzi we-filler, i-filler kufuneka ibe nesantya esithile sokuqina, ngoko ke kuya kubakho ukuqina ukusuka ngaphakathi ukuya ngaphandle emva kokuba ukuzaliswa kwenziwe. Ezi ntlobo zimbini ze-graphite fillers zohlobo olunye ezikhankanyiweyo apha ngasentla zi-braided fillers ezinenkqubo yokubumba ebotshelelwe zii-graphite fibers ezininzi, kwaye ukuqina kutsalwa yi-braided gap kwaye akukho mkhondo ucacileyo wokulangazelela ukwanda. I-graphite yokupakisha yohlobo lwe-ring yi-compack encinci ene-interior encinci. Emva kwexesha elide lokuma, ukuqina kwangaphakathi kuya kubonisa ii-cracks kumphezulu we-packing kwaye kukhulule le nxalenye yoxinzelelo. Olu hlobo lwe-filler luya kuhlala luzinzile kwaye aluyi kutshintsha emva kokuba kwenziwe i-crack ethile. Xa icinezelwe kwakhona, i-crack iyanyamalala kwaye i-rebound rate iyahlangabezana nemfuneko.

Ezi zilandelayo ziimfuno zobugcisa zeeringi zegrafiti eziguquguqukayo

Itheyibhile 2 Ukusebenza kwendandatho yokupakisha

| ukusebenza | iyunithi | isalathisi | ||

| Igrafayithi enye eguquguqukayo | I-Metal composite | |||

| isitywino | g/cm³ | 1.4~1.7 | ≥1.7 | |

| Umlinganiselo woxinzelelo | % | 10~25 | 7~20 | |

| Izinga lokujika kwakhona | % | ≥35 | ≥35 | |

| Ukunciphisa ubunzima bomzimba obufudumeleyo | 450℃ | % | ≤0.8 | —- |

| 600℃ | % | ≤8.0 | ≤6.0 | |

| I-coefficient yokungqubana | —- | ≤0.14 | ≤0.14 | |

| a Kwizinto ezidityanisiweyo zesinyithi, xa iqondo lokunyibilika kwesinyithi liphantsi kunobushushu bovavanyo, olu vavanyo lobushushu alufanelekanga. | ||||

3. Malunga nokusetyenziswa kokupakisha i-graphite

Ukupakisha igrafiti kusetyenziswa kwindawo evalekileyo phakathi kwesiqu sevalvu kunye ne-packing gland, kwaye ukupakisha kukwimeko yokuxinwa ngexesha lokusebenza. Nokuba kukupakisha kohlobo olunye okanye ukupakisha kohlobo lweringi, akukho mahluko kumsebenzi wemeko yokuxinwa.

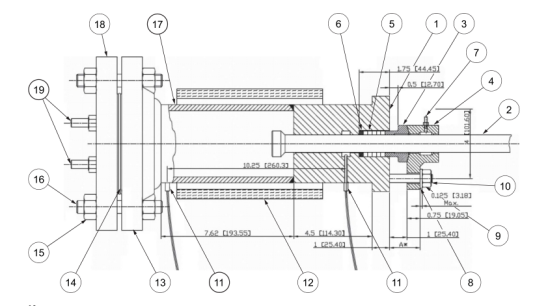

Oku kulandelayo ngumzobo wemeko yokusebenza kokupakisha (umfanekiso wovavanyo lokutywina ukupakisha)

Ixesha lokuthumela: Julayi-12-2021