1. Inkcazo yohlobo lweGraphite Packing

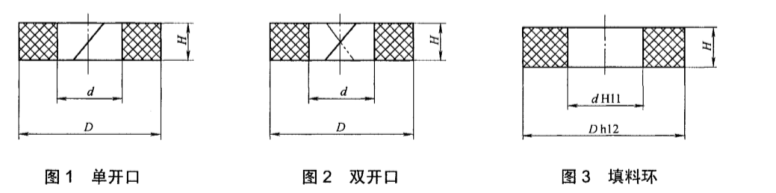

Kukho ezi 3 ntlobo zilandelayo zezihluzi eziqhelekileyo ezisetyenziswa kwi iivalve

Ukupakishwa okusetyenziswe kule projekthi luhlobo olulodwa lokuvula kwi-Figure 1 kunye nokupakishwa kwe-ring-shaped kwi-Figure 3. Iifoto zangempela zilandelayo:

Umzobo 1 Ukupakisha kohlobo olulodwa lokuvula

Umzobo 3 Ukupakisha umsesane wokupakisha

Imisebenzi yokusetyenziswa kwezi zipakethe zimbini zingasentla ziyafana, umahluko ulele kwiimeko ezahlukeneyo zokusetyenziswa. Ukupakishwa kokuvula okukodwa kukulungele ukutshintsha indawo yokupakisha ngexesha lokugcinwa kwe-valve yemihla ngemihla. Ukupakisha kunokutshintshwa kwi-intanethi, kwaye ukupakishwa kwendandatho yokupakisha kukulungele ukugqithisa i-valve. Isetyenziselwa ukuchithwa kunye nokugcinwa.

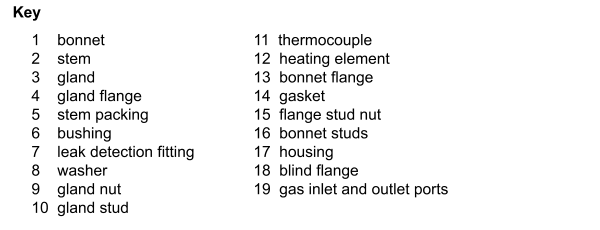

2. Inkcazo yeempawu zokupakisha igraphite

Ngokweemfuno zobuchwepheshe bokwenziwa komatshini wokuzalisa, umzalisi kufuneka abe nesantya esithile sokuqina, ngoko kuya kubakho ukuqiniswa ukusuka ngaphakathi ukuya ngaphandle emva kokuba ukuzaliswa kwenziwe. Ezi ntlobo zimbini zikhankanyiweyo ngasentla zohlobo olulodwa lokuvula i-graphite fillers zizizalisi ezilukiweyo ezithi inkqubo yokubumba iphoswe yimicu emininzi yegraphite, kwaye ukomelela kutsalwa ngumsantsa ophothiweyo kwaye akukho mkhondo ucacileyo wokulangazelela ukwanda. Ukupakisha uhlobo lweringi yokupakisha igraphite kukupakishwa okuxineneyo kunye nengaphakathi elixineneyo ngokwentelekiso. Emva kwexesha elide lokuma, ukuqina kwangaphakathi kuya kubonisa ukuqhekeka kwindawo yokupakisha kunye nokukhulula le nxalenye yoxinzelelo. Olu hlobo lokuzalisa luya kuhlala luzinzile kwaye alutshintshi emva kokuqhekeka okuthile. Xa icinezelwe kwakhona, ukuqhekeka kuyanyamalala kwaye izinga lokuphindaphinda lihlangabezana nemfuneko.

Oku kulandelayo ziimfuno zobugcisa zamakhonkco egraphite aguquguqukayo

Itheyibhile 2 Ukupakisha ukusebenza kweringi

|

ukusebenza |

iyunithi |

isalathisi |

||

|

Igraphite eguqukayo enye |

Metal composite |

|||

|

itywina |

g/cm³ |

1.4~1.7 |

≥1.7 |

|

|

Umlinganiselo woxinzelelo |

% |

10–25 |

7-20 |

|

|

Ireyithi yokubuyela kwakhona |

% |

≥35 |

≥35 |

|

|

Ukwehla kobunzima bobushushu a |

450℃ |

% |

≤0.8 |

—- |

|

600℃ |

% |

≤8.0 |

≤6.0 |

|

|

I-Coefficient of friction |

—- |

≤0.14 |

≤0.14 |

|

|

a Kwiingqungquthela zetsimbi, xa indawo yokunyibilika yentsimbi iphantsi kunobushushu bokuvavanya, olu vavanyo lobushushu alufanelekanga. |

||||

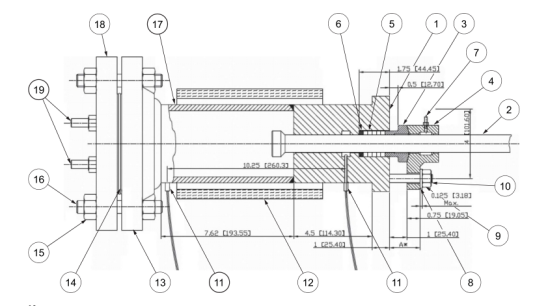

3. Malunga nokusetyenziswa kwegrafu yokupakisha

Ukupakishwa kwegraphite kusetyenziswa kwindawo evaliweyo phakathi kwesiqu sevalve kunye ne-packing gland, kwaye ukupakishwa kukwimeko ecinezelekileyo ngexesha lokusebenza. Ingaba luhlobo olulodwa lokuvula ukupakisha okanye ukupakisha uhlobo lwendandatho yokupakisha, akukho mmahluko kumsebenzi wobume obucinezelweyo.

Oku kulandelayo ngumzobo wemeko yokusebenza yokupakisha (umfanekiso wovavanyo lokutywina)

Ixesha lokuposa: Jul-12-2021